Case Study : Fabric First

![Case1 screenshot 20250805 222810 rightmove[1]](https://epchomeenergy.co.uk/wp-content/uploads/2025/12/Screenshot_20250805_222810_Rightmove1-1024x549.jpg)

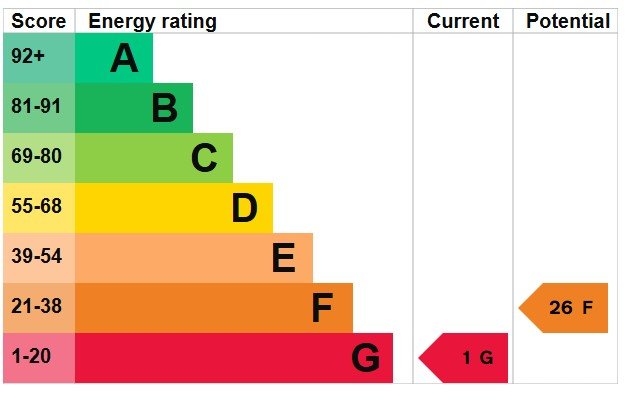

This Case study was actually my home and my introduction into heat loss and heat pumps back in 2011. The property was a complete renovation project the EPC for the property was a G with one single point and produced 20 tons of CO2. The property was heated by coal fires and temporary heaters.

With lots of research and interest in the Haf Haus of extremely low energy homes that put forward a fabric first principle of insulate insulate then add technology. The plan was a full renovation and extending the house although this was not fully competed somewhat maybe because of the over time and money renovation to above the building regulation requirement.

Not only interested in energy effciency i wanted a nice home that was cheap to run and took advantage of the surrrounding views. I decided early on that a heatpump was the way forward as i did not want to install oil heating. I commited to a IVT 7KW ground source heat pump this before the Green Deal brought any funding but did take advantage of it when it was brought in although I did change suppliers which did add complication as the introduction of the goverment funding increased supply costs which did create some complications.

![Case1 screenshot 20250805 222818 rightmove[1]](https://epchomeenergy.co.uk/wp-content/uploads/2025/12/Screenshot_20250805_222818_Rightmove1-1024x638.jpg)

![Case1 screenshot 20230630 083144 facebook[1]](https://epchomeenergy.co.uk/wp-content/uploads/2025/12/Screenshot_20230630_083144_Facebook1-1024x779.jpg)

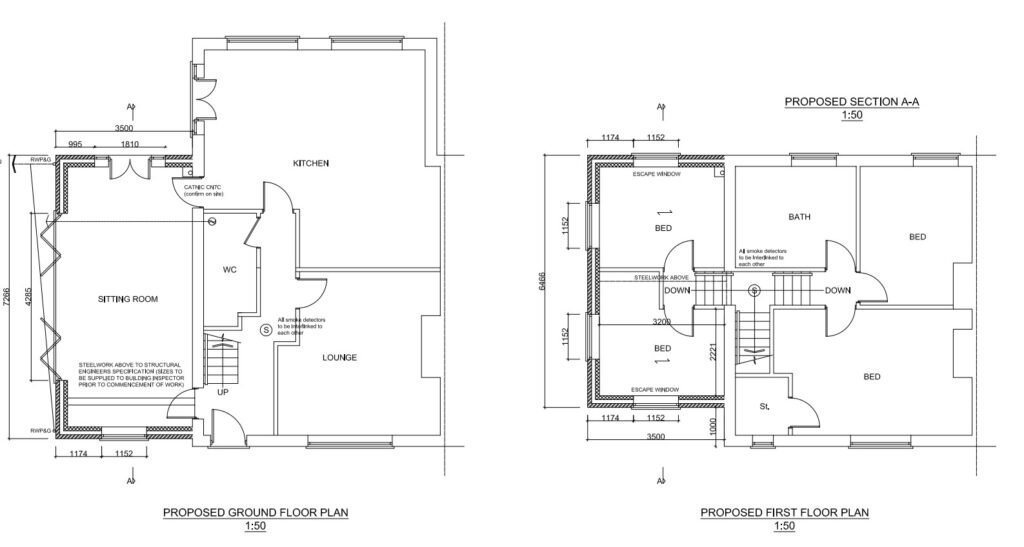

The heat pump install was installed under the MCS certification and used a MS3005 heat loss calculations based on my final building plans. But on the building control the extension was overglazed and they required evidence a whole house SAP calculation. Using the MS3005 as a baseline I documented the planned increasing in insulation to prove that the property was ebullient without having an SAP heatless calculation.

This included 75mm PIR internal insulation on the existing house walls which were cavity filled with Eco bead. 400mm under floor ESP throughout, Extension walls to have 50mm internal insulation and kitchen roof to be 100mm over the rafters and 100mm in-between, The loft was 350mm mineral wool. The main aim was trying to acheve a 0.1 U value on all the elements.

Not knowing as much as I do today but I was learning about whole house heating and open zones which Heat Geek and many low temperature heating installs promote today. This included that heat pumps like to have long run times and do as little lifting of outside to inside temperature as possible. I designed the ground floor slab to be one big storage heater. The concrete is 6 inches thick which is 22 tonnes of concrete with the heating pipes tied to the rebar results in 5.4Kwh to increase the temperate by 1 degree. The floor has 600 meters of 15mm pipe installed to transfer that heat and produce 1.5- 2-hour heat pump runs. With a zero outside temperature the flow temp is 35 degrees with a 20-21 internal temperature.

The GSHP uses a horizontal ground collector with two horizontal slinky collectors 300 meter each in length.

As the house stands now the EPC is a C69 and produced 0.8 tonnes of CO2 with the side extension completed to building standards with no extra internal insulation the house would be a C77 with 0.8 tonnes of CO2 per year. This is very good with bi folding doors and over glassed

The house is plumbed for Mechanical Ventilation Heat Recovery if fitted the EPC would be a B82

Adding 7 Kw of Solar would be A103 and net Zero emissions over the year.

You can find a more in-depth article on my heat pump install Here